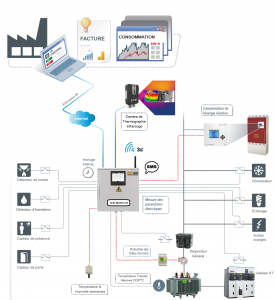

SUB-Monitor

Supervision and monitoring of transformer stations

The proper operation of the MV/LV transformer station is essential to ensure continuity of service for industrial units and tertiary buildings. A problem at this level can result in production lines being shut down and services stopped for long periods of time, ranging from several hours to several days in some cases.

In addition, access by outsiders (management personnel, maintenance companies, etc.).

The main points to control in a MV/LV substation are :

- Transformer temperature: It gives a direct indication of the load and operating conditions of the transformer. Temperature is a stressor for resin insulators and a chemical and physical alteration factor for mineral insulating oil for immersed transformers. When it exceeds a certain threshold, it can strongly accelerate the aging of these insulators.

- Other alarms from the transformer’s DGPT2 device

- Temperature distribution : it gives a precise idea of the good oil circulation in the immersed transformers, which allows to detect and anticipate many internal problems, such as the need for purging, …

- Ambient temperature in the station or cabin

- Humidity level and dew point calculation, which have a considerable impact on the insulation of medium voltage cells and transformer insulators.

- The load level of the transformer. This depends on the intensity of the current flowing through it, but also on the iron losses caused by the circulation of harmonic currents. Measuring and monitoring the transformer’s k-factor allows the actual load level of the transformer to be calculated and the life of the transformer to be maintained.

- The main electrical parameters of the installation: currents, voltages, powers, power factor, frequency, energies, harmonics, etc.

- The load curve: monitoring of active and reactive power calls by time slot,

- Electrical disturbances, power outages and voltage quality events: this is the most suitable point of the installation to measure and detect voltage quality events, according to the EN50160 standard, because it represents the point of coupling to the public grid (PCC) but also because it is at this level that all the harmonic currents created by the loads of the plant or the building go up.

- The total earth leakage current in the case of TT and TNS systems, or the overall insulation level in the case of an IT system

- The operating status (On/ Off/ Fault) of the protection and control equipment: status of the cells, the general circuit breaker, etc.

- The operating status of the compensation battery when it is present (reactive power, number of steps engaged, alarms generated, rate of capacity loss, etc.)

- Alarms coming from fire control units or access control units when they exist

- Monitoring of access to the workstation: time stamping of accesses, number of accesses per period, etc.

In addition to the monitoring and recording of these parameters, the sending of alarms in real time ensures effective and rapid interventions, when necessary, allowing the containment of problems as soon as they occur, before they have time to cause irreparable damage such as :

- Overheating,

- Flooding (detection of water or oil at ground level),

- Insulation or current leakage problems

- Protection triggers

- Access by a stranger,

- Application for assistance from a single person,

- Etc.

Advantages :

- Measurement, recording and monitoring of the temperature of the transformers, the premises, the operating status of the equipment and the main electrical parameters of the installation,

- Power quality monitoring according to EN50160

- Management of the ventilation and/or air conditioning of the station

- Remote control and remote management: remote closing / opening of protection equipment, manually or automatically programmed according to a calendar or predefined events.

- Monitoring of access to the station with time stamping, sending of alarms and recording of video or images (even in the dark)

- Local alarm: siren and/or indicator light (access to the station, high temperature, protection trip, or any other monitored parameter)

- Sending alarms by SMS: personalized alarms, on all monitored parameters.

- Sending messages by e-mail: personalized messages, on all monitored parameters.

- Real-time video surveillance (with thermal camera)

- Supervision in the form of graphic screens via the Internet

- Report generation (load curve, electricity bill simulation, power quality evaluation according to EN50160, number and duration of accesses, etc.)

- Ethernet connection

- Extendable system: possibility to add other measuring devices or equipment communicating in Modbus TCP or Modbus RTU

- Integrates with existing SCADA, … supervision solutions

Application Types

Remote or isolated sites

Delivery stations

Transformer stations